How Is Peanut Butter Made? The Answer Might Surprise You.

You might not NEED to know the answer to the question “How is peanut butter made” in order to make a great peanut butter cookie or pie but the process is very interesting.

Making peanut butter is a lengthy yet simple step-by-step process. The peanuts must first be planted and collected. They are then shelled and roasted dry. After that, they go through a cooling and blanching procedure to prepare them for grinding. The peanuts are then ground and put into jars.

Peanut butter manufacture was totally manual until the 1920s. The efficiency of the production process has considerably enhanced because to mechanical farming and harvesting. The world’s largest peanut butter facility produces over 250,000 jars every day. The production method of peanut butter will be described in full in this article.

Materials in the Raw

Approximately 90% of peanut butter is made up of peanuts that have been carefully picked by the farmer, roasted, blanched, and ground after manufacture. In addition, each 500 gram jar of peanut butter may contain approximately 1100 nuts. To increase smoothness, spreadability, and flavor, other additives such as salt (1.5 percent), hydrogenated vegetable oil (0.125 percent), dextrose (2 percent), and corn syrup (2 percent) are added to the product.

How is Peanut Butter Made- The Production Methodology

Peanut Planting & Harvesting

Peanuts are harvested in September after being sown in April or May. The peanut is a flowering plant with yellow flowers. After a period of time, the flower petals wilt, signaling the nuts’ underground growth. Peanuts are harvested from vines using portable motorized pickers and transported to warehouses for cleaning.

Blowers remove dust, sand, vines, twigs, leaves, and empty shells during the cleaning process.

The Shelling Process

The process of shelling nuts involves removing the outer layer. Peanuts are run through a succession of rollers that crack them throughout this process. After that, the cracked peanuts are passed through a series of screens, blowers, magnets, and destoners.

They’re tossed, softly tumbled, then blown with air until all the shells and rocks are gone. The peanuts are assessed for size, color, flaws, and broken skins after they have been shelled. Defective peanuts are discarded, while healthy peanuts are bagged and ready to be processed.

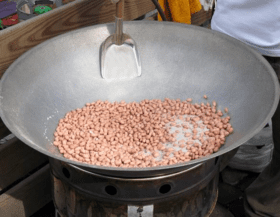

Dry Roasting

Dry Roasting

Dry roasting is a method of applying heat to dry foods without using any oil or water as a carrier. The peanuts are roasted in a continuous rocking motion through a hot air roaster. This action ensures that the nuts are uniformly roasted. When the frying is finished, the color of the peanuts changes from white to light brown, as indicated by a photometer.

Cooling The Nuts

To stop the heating process, the peanuts must be quickly chilled. This keeps them moist and lubricated, preventing them from drying out. The hot peanuts are sent directly from the roaster to a perforated metal cylinder, where suction fans suck a considerable volume of air through. The temperature of the peanuts is raised to 30 degrees Celsius.

What is Blanching?

Blanching involves running the peanuts through rubber belts to remove the outer skins that remain after roasting.

The kernels are split in half during this procedure, and the heart of the peanuts is removed because it has a bitter taste. Finally, on a conveyor belt, the blanched nuts are mechanically sifted and examined to remove any burned or rotten nuts.

The Grinding Process

After blanching, the peanuts are ground into a paste in a grinder with other ingredients. Two grinding procedures are normally required to make peanut butter. The first uses a high-speed comminutor to grind the nuts to a medium grind, while the second uses a high-speed comminutor to ground the nuts to a fine, smooth texture.

The shearing and grinding operation of this machine turns the hard peanuts into a silky paste. About 2% salt, hydrogenated vegetable oil, dextrose, and corn syrup are added to the peanuts as they are fed into the grinder.

The stabilizer, hydrogenated vegetable oil, prevents the oil from gathering at the top of the peanut butter container.

The temperature of the peanut butter rises to 60 degrees Celsius after grinding. As a result, after mixing, the paste must be cooled to 38 degrees Celsius. Peanuts are kept under continuous pressure during the grinding process to avoid the production of air bubbles, which could cause oxidation. Because a decreased oxygen level makes it more difficult for bacteria to survive and cause deterioration, reducing oxidation extends the shelf life of peanut butter. Furthermore, the peanut butter is de-aerated, stabilized, and ready for packaging after grinding.

Packaging The Peanut Butter – See How Is Peanut Butter Made

The freshly made peanut butter is poured into jars in a continuous stream under even pressure during packaging. When it comes to sealing peanut butter jars, manufacturers utilize vacuum packing once again to prevent oxidation. The peanut butter is left undisturbed after it is placed in final containers until it has completely solidified. The jars are then labeled, packed into boxes, and stored until they’re ready to be dispatched to wholesalers or clients like you!

The video below shows you how peanut butter is bottled at the factory. I find this to be mesmerizing.

How is Peanut Butter Made at Home

Some store-bought peanut butters contain ingredients we don’t want in our bodies, such as palm oil and a ton of added salt, sugar, or chemicals. Making your own peanut butter is a simple method to know precisely what you’re eating, and it also allows you to experiment with flavors, salt amounts, and even the nuts you use, ranging from almond to cashew to hazelnut.

When you make your own nut butter, you have complete control over the flavors you use. We all have different tastes, and if you’re feeding kids, it’s a great opportunity to get them interested and invested in their own healthy breakfast options.